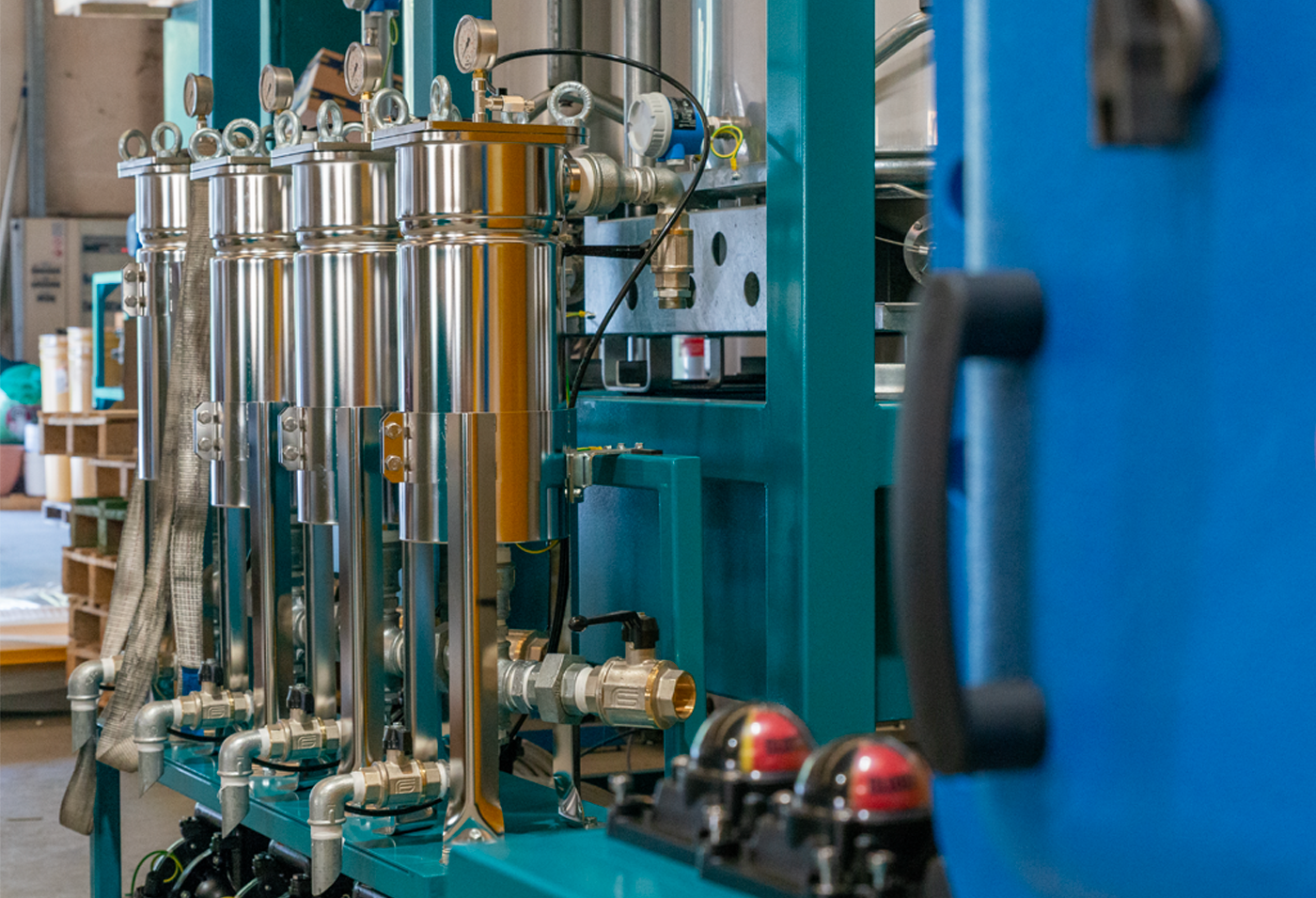

Since 1997 we have been developing innovative and automated integrated systems suitable for ensuring efficient and sustainable washing processes and allowing high savings in management costs. Since 1997 we have been designing, manufacturing and installing systems for automated washing and recovery of industrial containers. We have always believed in innovation. We also believe that the know-how of our team of experts is our best tool for providing you with a customized technological solution, specifically designed for your needs. Our product range includes machines for low or high pressure washing processes (at 6, 18, 150, 200, 250, 350 and 400 bars with water and solvent at 6, 18, 40 bars). Hot washes (up to 80 °C), only with water or in combination with soda or other cleaning products are also possible. In most cases, our washing systems for industry are used in closed loop, allowing you to reduce management costs- Thanks to a filtration system it is possible to significantly reduces the quantity of the washing liquids (water or solvents) needed for the processes. However, in industries such as food, cosmetics or pharmaceuticals, it is necessary to operate in an open loop, without recirculation. The use of high-pressure pumps and high-pressure washing heads (also combined with brushes at low pressure) will speed up your washing process and allow you to get high quality final results in conditions of maximum safety for the operators. 50 – 220L secchi, taniche, latte, bidoncini 120 – 240 – 360 – 720 – 1100L 220 L History

We are present all over the world, with over 600 plants installed. Each one of our projects has been designed to maximize operational efficiency, guarantee excellent results, significant savings in management costs and reduce waste.

Our company

When a customer joins the CEB family, he will find a reliable partner who works with passion to create the most suitable solution for his industrial washing processes.

Innovative washing systems

Containers Allowed

on Our Machines

Mobile mixing tanks

Conical mixing tanks

Fixed mixing tanks on mezzanine

Mixers, dispensers, HV mixers

HDPE IBCs

HDPE conical base IBCs

Stainless steel IBCs

HDPE drums

Plastic buckets

HDPE jerrycans

HDPE MSW bins

Metal containers

Metal buckets

- Home

- Company

- Production

Washing of

Machine type

- Washing head

- High pressure washing head

- Automatic lines

- Nylon brushes

- Steel brushes

- Special machines

Detergent

- News

- Contacts