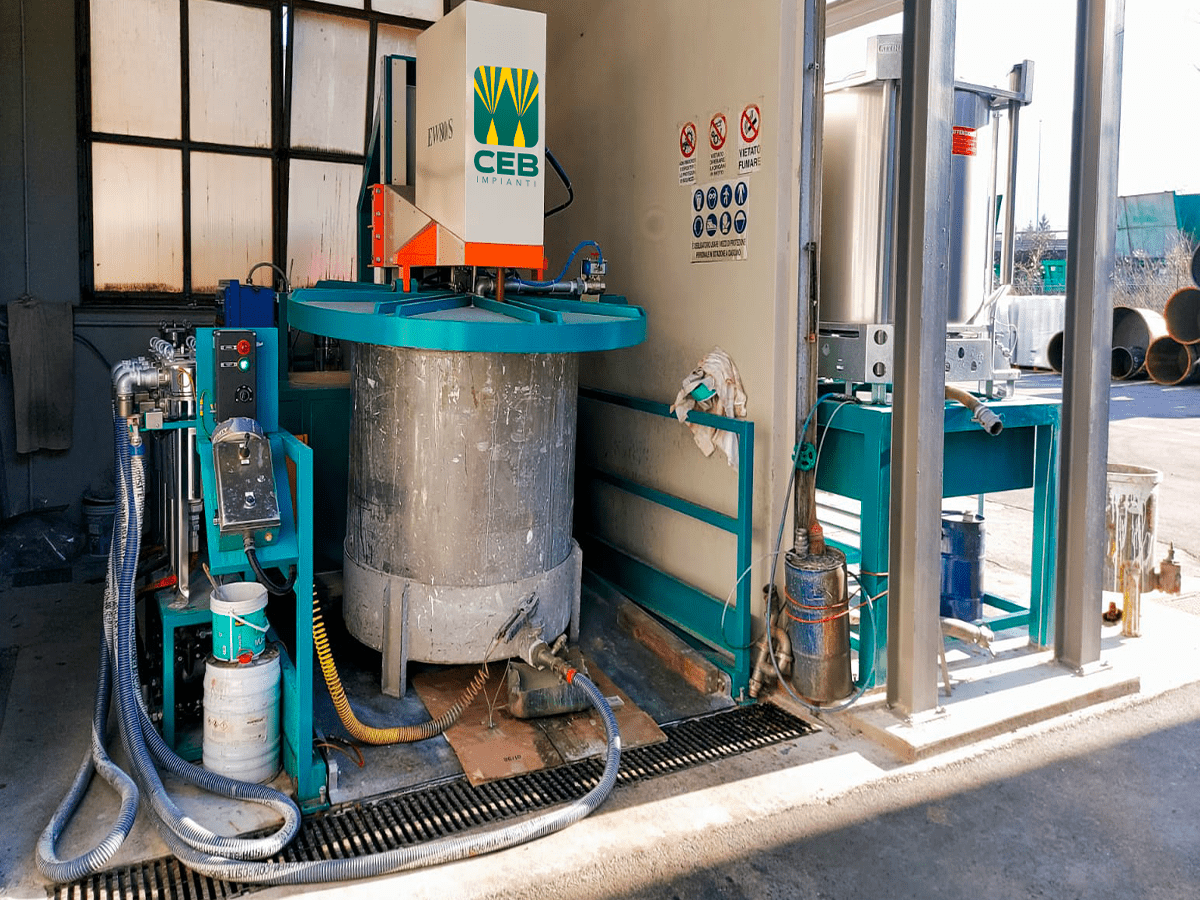

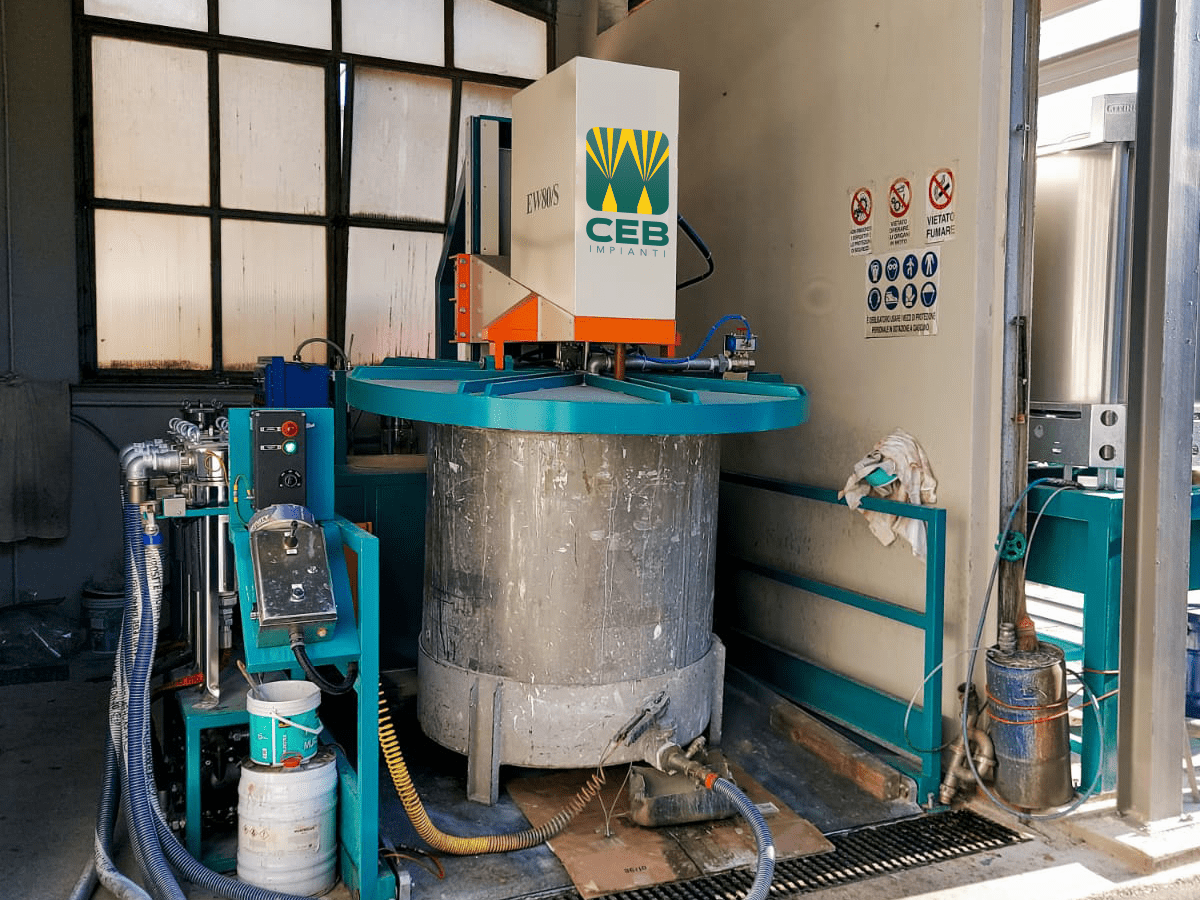

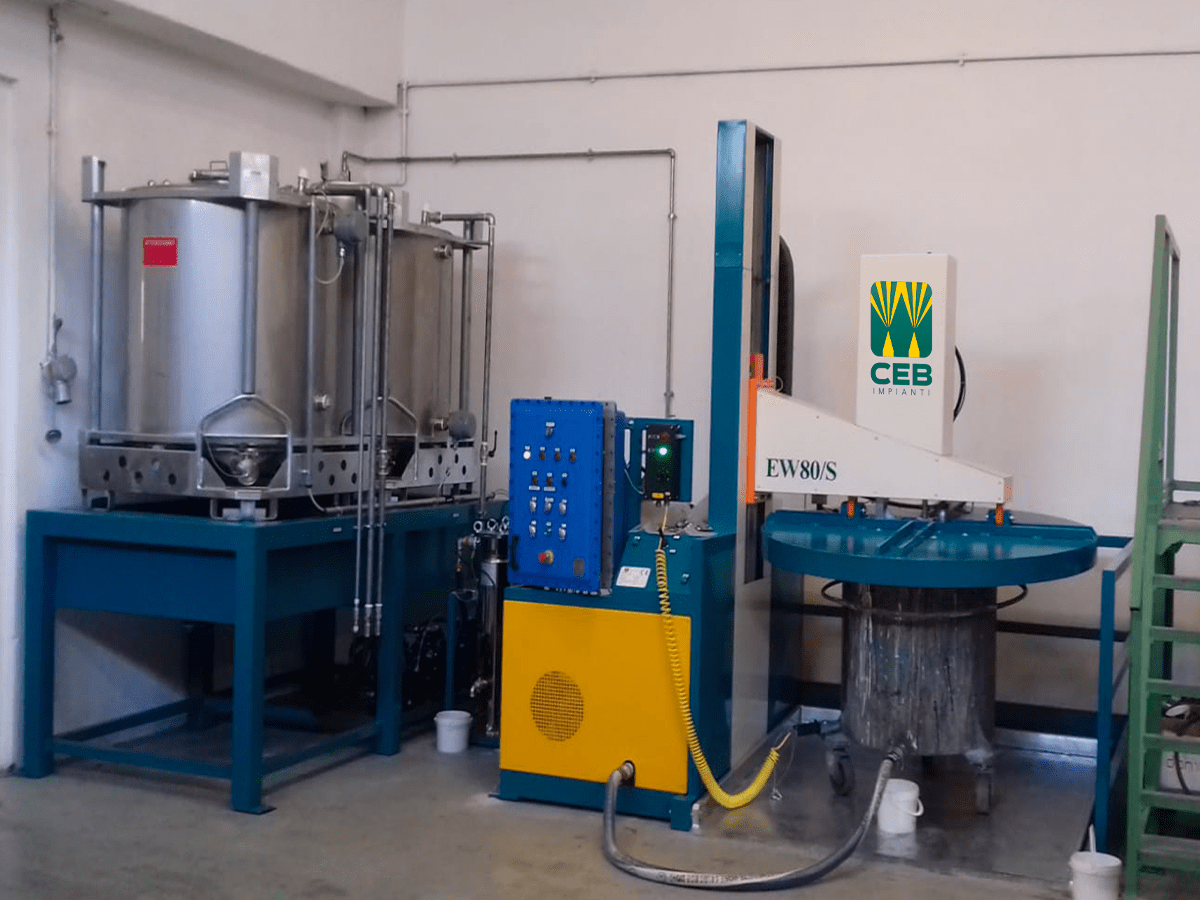

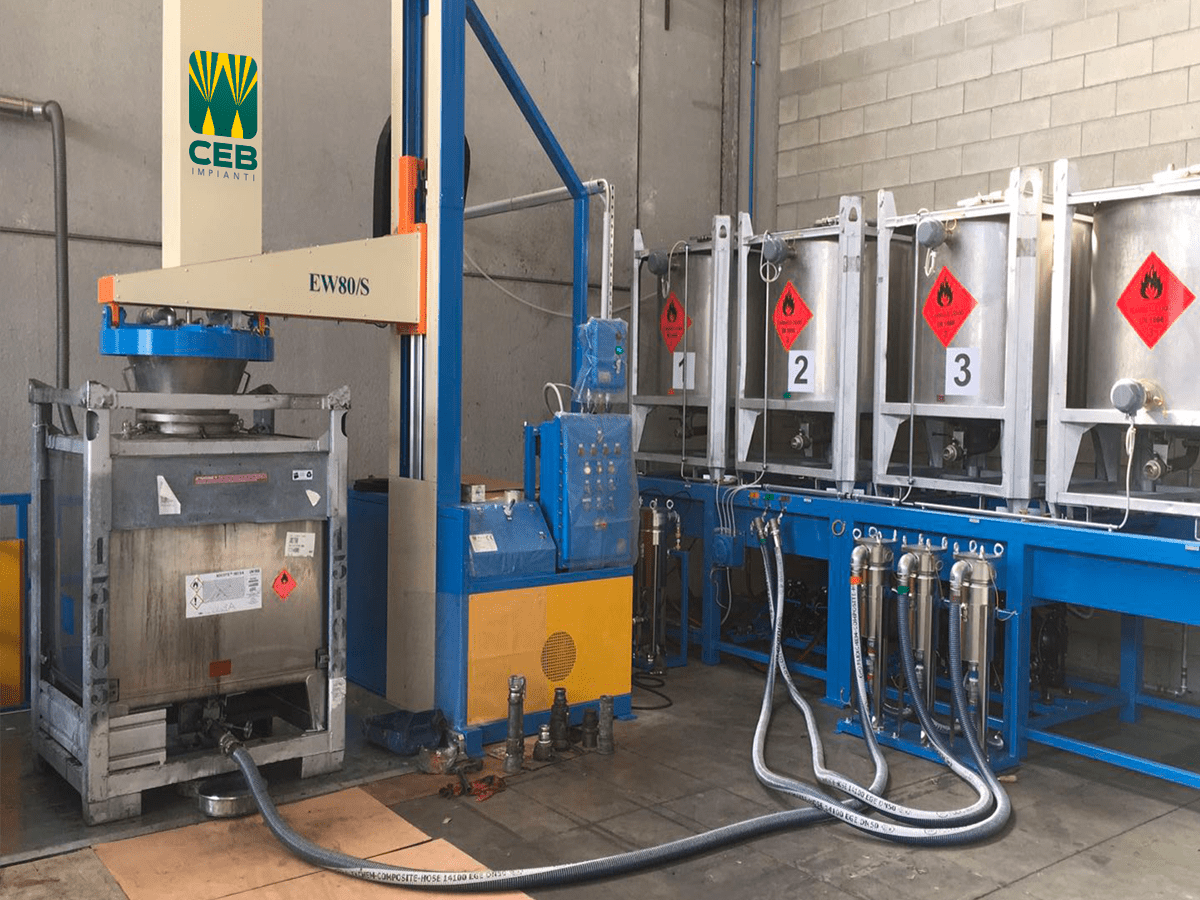

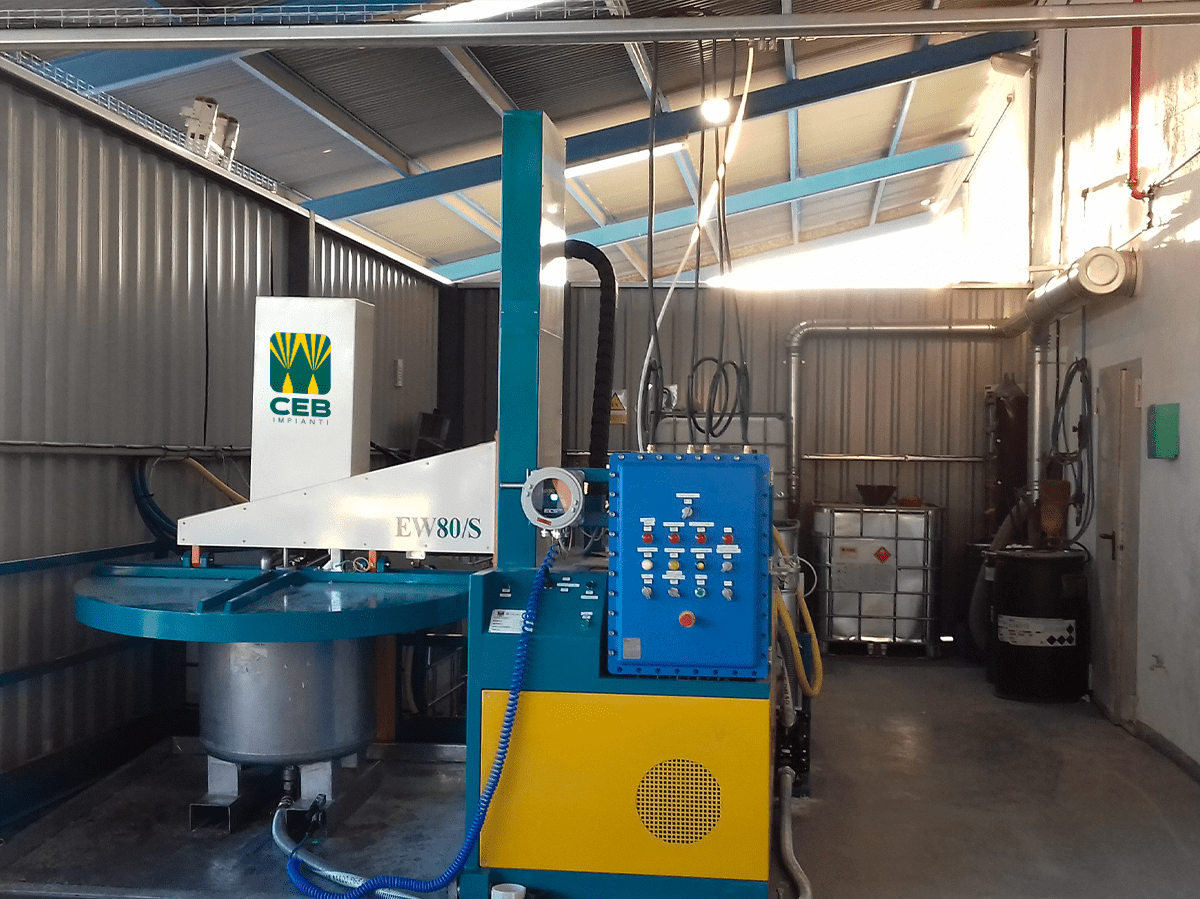

Machine with tilting platform for open top mixing tanks, IBCs in HDPE and stainless steel. Three possible cycles: Eco – Standard – Long. Average cycle duration: from 3 to 5 minutes (loading and unloading time excluded) Available with water collecting basin and grilled platform. Possible combination with EWEC or EWEC2 for drum washing. Cycle with water and/with detergent in three phases (prewash, wash and rinse) 40 max 40 bar 250 max 250 bar For the S versions For A versions EW80

EW80

The containers must have a lower drain valve (from 1,5”, 2”, 2,5” or 3″).

Washing with open or closed cycle with 2 or more washing and rinsing liquid storage tanks. Model /A

Available models

EW80/S – C/V/CV

EW80/A -250/400 – C/V/CV

400 max 400 bar Available options

Photo and Video Gallery

- Home

- Company

- Production

Washing of

Machine type

- Washing head

- High pressure washing head

- Automatic lines

- Nylon brushes

- Steel brushes

- Special machines

Detergent

- News

- Contacts